Industrial Machinery

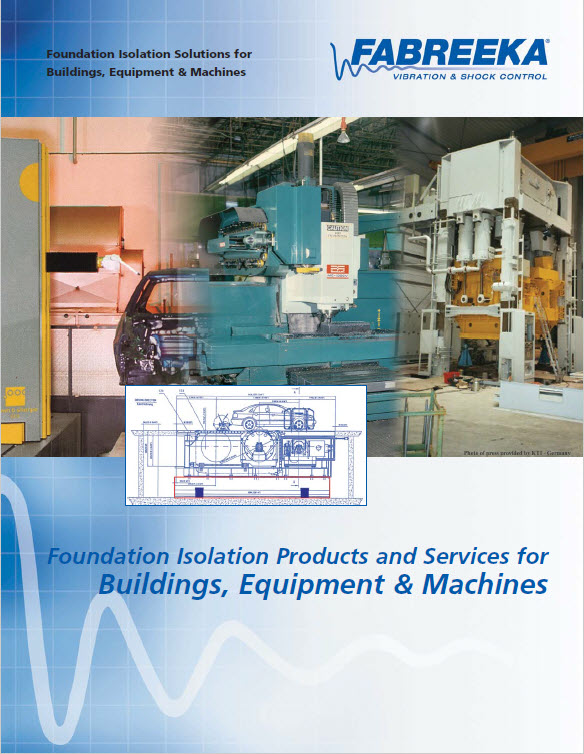

Designing foundations supporting machine tools requires sound engineering procedures for a reliable result. An incorrectly designed foundation is extremely difficult to correct once installed. Consequently, many engineers use Fabreeka isolation materials and machine mounts, knowing that they provide vibration isolation and leveling for proper machine tool installation.

Fabreeka also provides solutions for applications when it is not desirable or feasible to mount a machine directly on vibration isolators. For example, installing vibration isolators on a machine whose frame or bed requires a stiff connection can cause bending, relative displacement or sagging and other problems, even when the floor is sufficiently rigid. For cases like this, Fabreeka recommends that the frame or bed is attached to a properly designed concrete foundation, which is then supported on appropriate isolators for the application.

In many cases, manufacturing and quality control must co-exist in work-cells or in close proximity to one another. For certain machine tools, the permissible amplitudes of foundation vibrations in a manufacturing environment are very low. It often is very difficult to decrease or isolate vibration amplitudes by simply pouring a new foundation on soil. It also may not be possible to increase the stiffness or rigidity of the machine support structure, often floors, itself to avoid resonance or amplification of vibration. In these cases, unacceptable vibration amplitudes can be significantly reduced by using vibration isolators provided by Fabreeka.

Certain types of machine tools are not inherently rigid and therefore need a rigid support to maintain their prescribed accuracy. In other types of machinery, such as printing presses, consisting of articulated components, a rigid support may be needed to maintain the proper alignment of working parts. Fabreeka is a trusted partner and supplier in those cases as well.

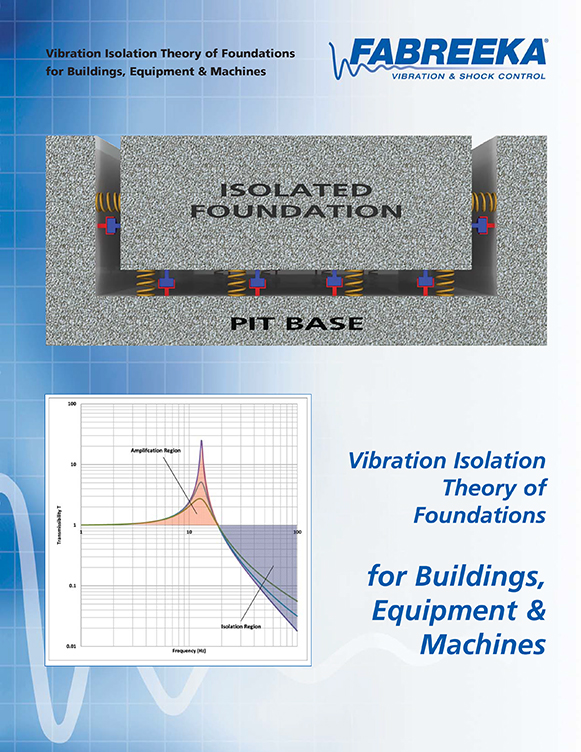

Engineering disciplines involved in the proper design procedures for isolated support foundations include theory of vibrations, geotechnical engineering or studying soil characteristics plus structural design and analysis.

Rotating Equipment

Fabreeka isolation products provide vibration control on a wide variety of rotating and reciprocating machinery and equipment that produce vibration during operation. Our engineers work closely with OEMs as well as end users to obtain the operating frequencies, dynamic or unbalanced loads, critical alignments and isolation mount specifications for a complete isolation solution.

In line with this, fans, blowers, motors, reciprocating and screw type pumps as well as compressors, engine-generator sets, gear boxes and generators are all applications where Fabreeka or Fabcel isolation pads, washers and bushings can be used. They are also the right choice to prevent roof top HVAC vibration.

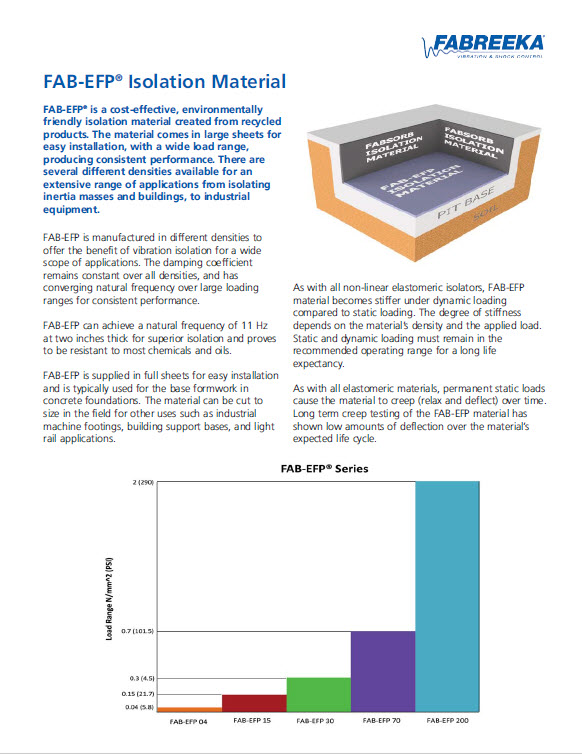

Depending on the rotational speed of the equipment and its weight support area, other Fabreeka products, namely Fabcel pad or machine support foundation isolation products such as FAB-EPM,

FAB-EFP and

Fabsorb are qualified.

Turnkey solutions are also available at Fabreeka, including demolition,

foundation design and concrete construction if a foundation is needed for rotating and other equipment.

Other Equipment

Fabreeka Crane Rail pad material is used to reduce vibration, stresses and mechanical wear and tear associated with bridge, gantry and ore crane operation, thereby reducing maintenance costs. Fabreeka

Crane Rail pads are designed to relieve girder stress, improve load distribution, eliminate mechanical wear of flange or cover plates, dampen vibration and reduce noise.

The laminated thermoset plastic (LTP) surface of the crane rail pad improves wear resistance, restricts lateral movement and provides a low coefficient of friction support for the rail. Tests performed by independent sources have shown up to 40% reduction in runway beam web stress and noise levels reduced substantially when using this Fabreeka product.

Automation equipment such as assembly and packaging equipment can cause vibration affecting other equipment or may be sensitive to vibration coming from the manufacturing floor. Vibration isolation products such as Fabreeka or

Fabcel pad plus isolation washers and Fabreeka bushings can be used to reduce the vibration to more acceptable levels, as is also the case with milling machines, CNC and other machine tools that may also be sensitive to factory floor vibration, influencing their accuracy.

Last, not least, injection molding machines can cause disturbing vibration to other machines when molds are opening and closing. Depending on the size, pad products supplied by Fabreeka can be placed directly under the machine or support the machine and a foundation to add rigidity.